PRODUCTS

Muffle

Founded in 2000, focusing on metal material modification, metal material development and application and shape control processing services, intelligent heat treatment equipment, robots and intelligent equipment manufacturing.

Compound corrugated muffle, commonly known as Bell, is the core component of high-end heat treatment furnace. German VDM nickel alloy steel plate is adopted for high quality, and Swedish outokumpu material is adopted for high cost performance. Outokumpu authorized to be sales, service & technical support base of stainless steel in China, STRONG TECHNOLOGY guarantees the products of the original factory. It is a wise choice of precision steel belt furnace, multi-purpose furnace and high-end mesh belt furnace.

View DetailsMuffle for Bright annealing furnace of stainless steel strip

From the research and development of stainless steel strip bright annealing furnace, many years of manufacturing and use experience, continuous research and development, from the muffle of oval furnace, through technical refining, the change into a composite corrugated muffle can compression, anti expansion, high temperature resistance, longer service life, material saving, cost saving, are our continuous progress of the source power! Muffle is the core component of annealing equipment, which is made according to different customer requirements.

View DetailsMuffle for Continuous bright annealing furnace of stainless steel strip

The compound corrugated muffle structure of the STRONG muffle won the national patent. It adopts the imported high temperature resistant nickel base material with Outokumpu of Sweden, which is specially designed to cope with the extreme high temperature challenge. The heating speed is fast, the temperature uniformity in the furnace is good, and the temperature disturbance in the furnace is small.

View DetailsCore accessories of Continuous stainless steel strip annealing furnace

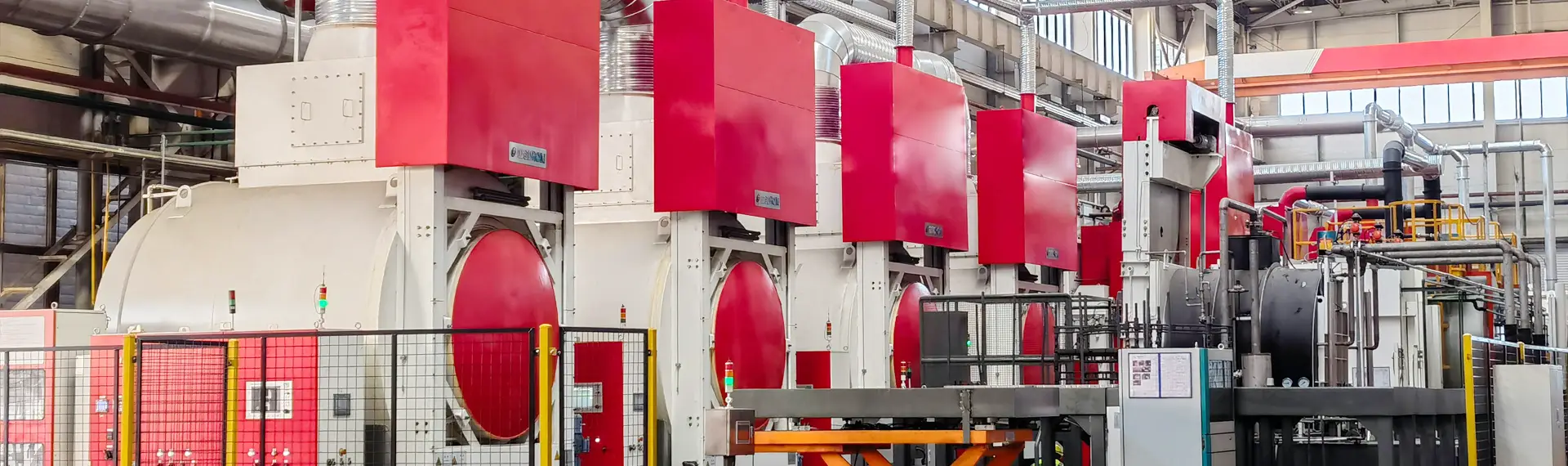

After the cold rolled of stainless steel, in order to remove the stress, the continuous bright annealing line for stainless steel strip of STRONG TECHNOLOGY is used. Through the protective atmosphere, 1050 ℃ high temperature annealing, cooling and rearrangement of elements, the surface of steel plate is bright and clean.

View Details