PRODUCTS

Strong Products

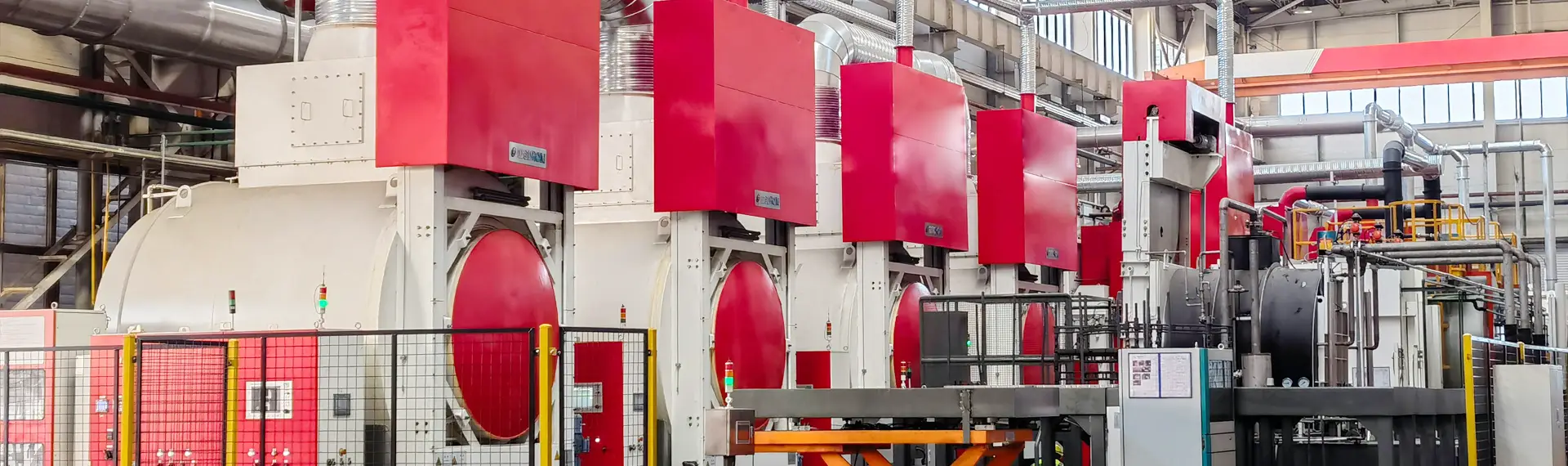

Founded in 2000, focusing on metal material modification, metal material development and application and shape control processing services, intelligent heat treatment equipment, robots and intelligent equipment manufacturing.

Continuous vacuum cold rolling strip coating equipment

The continuous vacuum cold rolling strip coating equipment is mainly for the coating of high-end decorative stainless steel plate, and the surface coating increases wear resistance. Decorative coating: application: continuous strip decorative plating, hardware, construction

View DetailsCoating equipment for decorative parts

Coating equipment for decorative parts, plate decorative plating STRONG coating: decorative coating: applied to various decorative materials Characteristic: it has the characteristics of strong corrosion resistance, high mechanical performance, long-lasting color surface, color change with different illumination angles, etc.

View DetailsCoating equipment for cutting tools

STRONG coating: hard film coating: applied to mould tools and parts Special coating equipment for superhard tool mould: the cutting tools made of high-speed steel and hard alloy can improve the surface hardness and self lubrication of the tools after coating, reduce the phenomenon of tool sticking, greatly improve the tool life, and reduce the processing cost. After coating, the mould also has the effect of improving its life. It is widely used in automobile, machine tool, chemical industry, hardware tools, medical devices, standard parts manufacturing and other fields. After the tool (cutter) is coated, the service life can be increased by 3-10 times, and the cutting efficiency can be increased by more than 30%. After coating, the service life of the mould can be increased 5-10 times and the friction force can be reduced. after PVD coating, the hardness can reach 3600hv. We can design all kinds of vacuum coating machines according to customers' requirements. The vacuum unit and electric control system can also be designed and configured according to the user's requirements.

View DetailsMULTI-ARC LON PLATING SYSTERM (PVD)

The development of equipment manufacturing industry puts forward the pursuit of high speed, high precision, high efficiency, intelligence and environmental protection for cutting process and tool performance; The multi-component alloying of the coating material makes the cutting tool obtain good comprehensive properties such as high wear resistance, low friction, good thermal stability and strong oxidation resistance. The coating process equipment also tends to be integrated, modularized and intelligent, so as to ensure that the coating technology is becoming more personalized, and the coating cutter has made great progress. Coating types: TiN、CrN、ZrN、TiCrN、TiAlN、TiAlCrN、ZrCrN and other multi-component composite coatings; nano multi-layer super dura, nano composite super dura, etc.

View DetailsVacuum multi arc ion plating coating machine

Our company provides vacuum Multi-Arc Ion Plating Technology and Multi-Arc Ion Plating Vacuum Equipment, which has been put into production. Order number: 0757-23322638

View DetailsPlate vacuum coating equipment

Plate vacuum coating equipment is suitable for plate vacuum coating. STRONG coating: thermal barrier coating: applied to generator and gas turbine blades for power generation, etc.

View Details