PRODUCTS

Strong Products

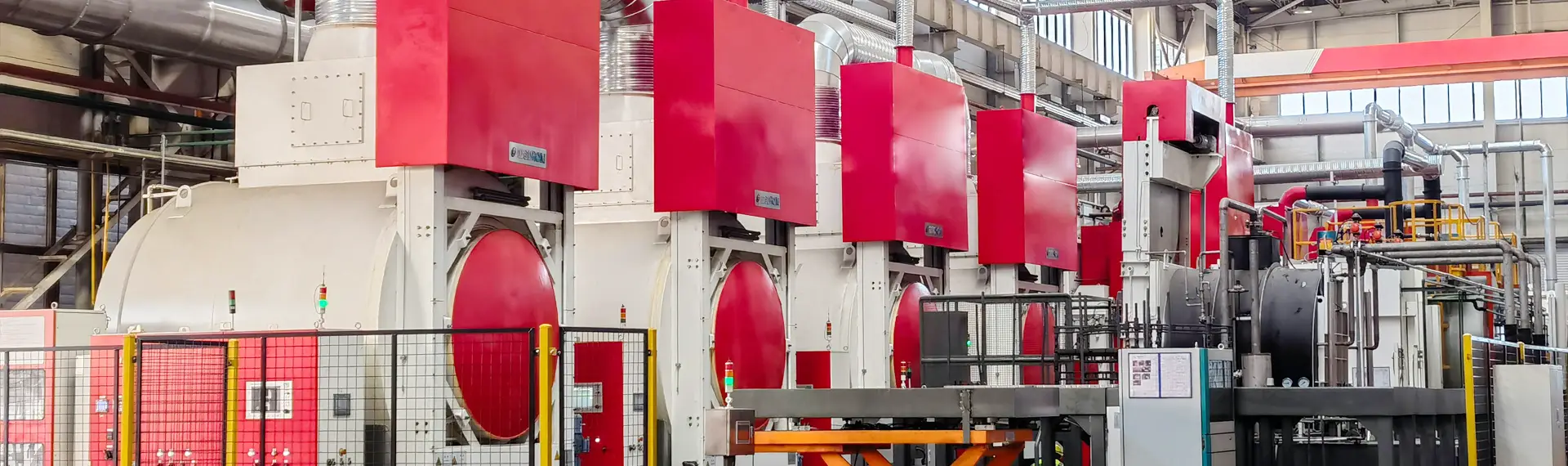

Founded in 2000, focusing on metal material modification, metal material development and application and shape control processing services, intelligent heat treatment equipment, robots and intelligent equipment manufacturing.

Intelligent heat treatment production line of mesh belt furnace

Characteristic: Intelligent heat treatment production line of mesh belt furnace is suitable for mass production of various small workpieces,such as carburizing, carbonitriding, quenching, oil quenching, water quenching and other heat treatment processes, processing screws, nuts, stamping parts, etc. Design different heat treatment solutions according to your different workpieces. Customized according to the product. Model: SW-810-9F Performance: temperature 950 ℃; Material: shell: low carbon steel Process: (1) carburizing, carbonitriding (2) controlled atmosphere quenching, isothermal quenching (3) oil quenching, water quenching Advantage: computer control

View DetailsBright annealing line for horizontal looper

Application: For continuous bright annealing of stainless steel strip, common steel, alloy steel, spring steel and copper. Belt thickness: 0.1 ~ 3mm Band width: 250 ~ 1450mm Liquefied Natural gas (LNG), liquefied petroleum gas (LPG) and diesel oil can be selected as the main heating mode of the furnace.

View Details1050 stainless steel strip bright annealing production line

200 series and 300 series cold-rolled stainless steel plate processing, 1050 cold-rolled stainless steel strip optimization of STRONG TECHNOLOGY continuous stainless steel strip bright annealing production line Advantage: 1: TV value reaches 15-18, and production capacity is 6 tons / hour. 2: Intelligent temperature control has high precision and low energy consumption. 3: Greatly improve the brightness and flatness of the board surface at the same time, and greatly increase the output.

View DetailsStrip degreasing and cleaning production line

Strip degreasing and washing production line is commonly known as stainless steel strip washing machine. After cold rolling of stainless steel strip, there is grease residue on the strip surface. After 950 ° ~ 1050 ° high temperature, the residue will adhere to the strip surface and affect the Smoothness. The strip washing machine adopts detergent to clean, brush to remove the residue, squeeze out the water and then dry to ensure that the steel strip entering the annealing furnace is clean; Degreasing and washing production line can be customized according to the capacity you need.

View DetailsVertical continuous bright annealing line (VBAL)

Process: Vertical continuous bright annealing for cold rolled steel coil strip Features: suitable for ultra-thin, ultra precision, scratch free precision strip Advantages: 1. Ultra thin; 2. Flat plate, not easy to crack; 3. Small annealing deformation of stainless steel strip,

View DetailsBright annealing line for continuous precision thin coils

Scope of application: petrochemicals, automotive industry, household appliances and electronic industrial products, etc.

View DetailsBright annealing line for horizontal looper (cold coal gas heated)

Bright annealing line for horizontal looper (cold coal gas heated) Advantage: lowest operating cost Scope of application: architectural decoration industry, civil tools, tableware, knives, etc

View DetailsBright annealing line for horizontal looper (LPG heated)

Bright annealing line for horizontal looper (LPG heated) Moderate operating costs Scope of application: architectural decoration industry, civil tools, tableware, knives, etc

View Details