PRODUCTS

Strong Products

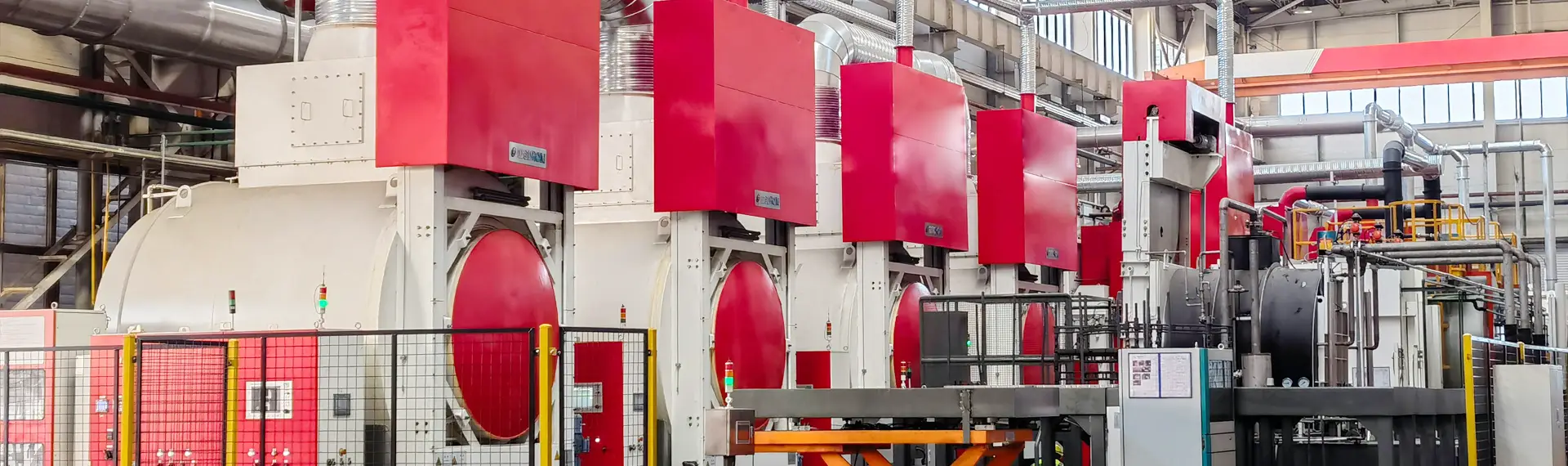

Founded in 2000, focusing on metal material modification, metal material development and application and shape control processing services, intelligent heat treatment equipment, robots and intelligent equipment manufacturing.

Powder metallurgy sintering heat treatment production line

Powder metallurgy is the pressing and forming of metal powder,a manufacturing technology of complex shape metal parts with high precision and high strength is obtained through subsequent sintering, heat treatment and other processing procedures. Compared with other metal forming technologies, such as forging and casting, this technology has advantages in material utilization, shape complexity and near net shape size control. As a high cost-effective part preparation method, P / M parts have unique advantages in cost and size, with very high cost-effective. Its advantages are as follows: 1) the parts are close to the final size, have good smoothness, reduce the follow-up processing cost, and minimize the loss of waste products; 2) It can produce complex or unique shape parts that cannot be manufactured by other processes; Due to the unique process of powder metallurgy, metal injection molding (MIM) can produce parts with highly complex shape features. 3) The porosity of the product can be controlled to meet the requirements of self lubrication and wear resistance of the product. 4) according to the calculation of economic advantages of powder metallurgy, compared with the traditional machining process, the powder metallurgy process can save 60% energy, the material utilization rate is up to 95%, the production process is green and the production cost is economic. Excellent P / M performance and wide application Compared with other manufacturing processes, P / M products have the advantages of material saving, energy saving, high accuracy, high consistency, complex structure, uniform composition, etc., and are widely used. At present, it is mainly used in automobile, industrial motor / control system, entertainment facilities, household appliances and other aspects, of which automobile industry is the main driving force of powder metallurgy, accounting for about 70% of the global average.

View DetailsContinuous brazing heat treatment production line

Continuous brazing heat treatment production line It is used for bright heat treatment of various industrial precision electrical materials, stainless steel, electronic hardware products, etc. Fabrication of brazing.

View DetailsBright annealing production line for stainless steel kitchenware

Stainless steel stretch material bright annealing, adopting protective atmosphere, stainless steel wash basin annealed.

View DetailsConveyor Belt Furnace (Guanghui Furnace)

The Conveyor Belt Furnace (also known as Guanghui Furnace) of STRONG TECHNOLOGY, with its unique design concept, simple equipment, reasonable structure, bridge type placement of workpieces, internal furnace pressure makes air not easy to enter;

View DetailsThe Main applications of Conveyor Belt Furnace: Hardware hardening, carburizing, tempering, brazing, sintering, quenching and cooling

View Details