11

2024

-

12

Strong Technology - Supporting the High Quality Development of the Titanium Industry

Guangdong Strong Metal Technology Co., Ltd. is a national high-tech enterprise. In July 2021, it was selected as a "Little Giant" enterprise by the Ministry of Industry and Information Technology. In 2022, it was named one of the top 100 enterprises for high-quality development of manufacturing industry in Foshan City. In 2023, it was recognized as a national industrial mother machine enterprise. For thirty years, Strong Technology has been deeply involved in the heat treatment industry, covering the research and development and production of intelligent heat treatment equipment, heat treatment processing services, development of new metal materials and manufacturing of key components, and design and construction of intelligent three-dimensional warehouses. The company's products are widely used in industries such as aerospace, weapons, automotive, electronics, machinery, metallurgy, etc., and are exported to Southeast Asia and Europe and America.

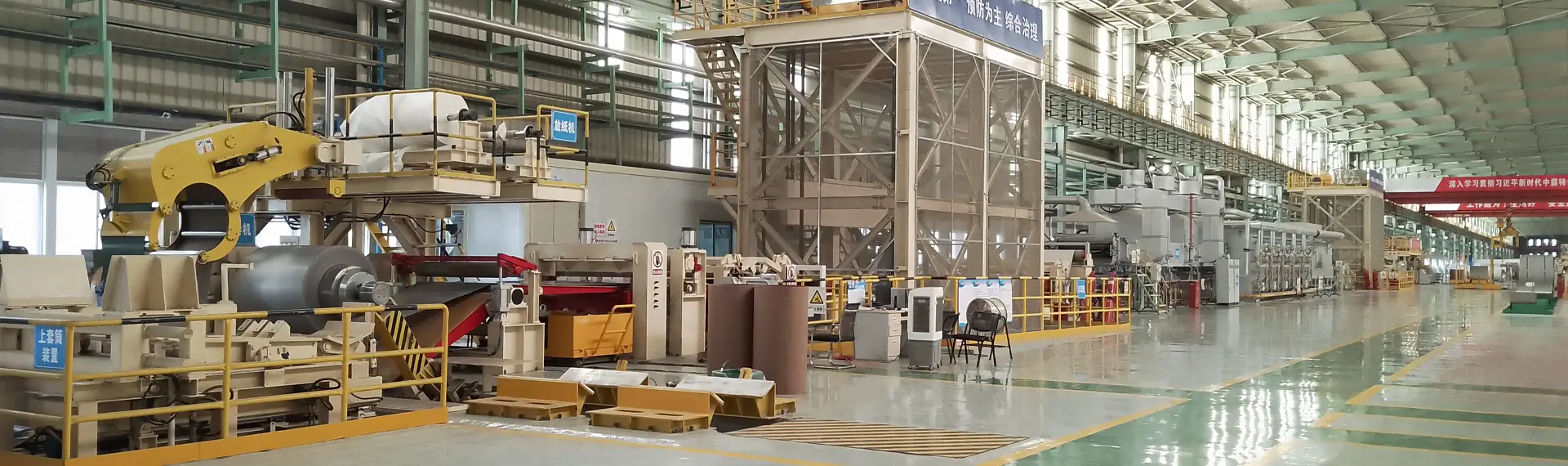

Foshan Manufacturing Base

Jiangmen Manufacturing Base

Has demonstrated outstanding professional expertise in cleaning and bright annealing of titanium alloy sheets. In the cleaning process, the company adopts internationally advanced cleaning technology and techniques to ensure that the dirt and impurities on the surface of the rolled titanium alloy plate are thoroughly removed. A strict cleaning process can effectively improve the surface quality of titanium plates, laying a good foundation for subsequent processing and use. The company is able to provide personalized cleaning for titanium alloy plates of different specifications and applications, meeting the diverse needs of customers.

In terms of annealing treatment, Strong Technology has a young and professional design team and mature annealing process. The annealing process can eliminate the internal stress generated during the processing of titanium alloy plates, improve the plasticity and toughness of titanium plates, and enable them to have better mechanical properties. The company's technical team strictly controls key parameters such as annealing temperature, holding time, and cooling rate, to ensure that every annealed titanium alloy plate meets high-quality standards.

Strong Technology Company, with its exquisite technology and strict quality control system in the field of cleaning and annealing of titanium alloy plates, has provided high-quality titanium alloy plate annealing production lines, precision cleaning lines and other heat treatment intelligent equipment to well-known industry enterprises such as Jiangsu Shengpo New Material Technology Co., Ltd., Wuxi Zhongcai New Material Co., Ltd., Baoji Titanium Industry Co., Ltd., and Hunan Xiangtou Goldsky Titanium Metal Co., Ltd., making positive contributions to the development of various industries.

Service hotline|+86-0757-23322638

Website|en.strong-ht.com

Address|No.32 Shizhou, Chencun, Shunde, Foshan, Guangdong 528313,PRC.

Keywords: continuous stainless steel strip annealing furnace

In the third quarter of 2024, all departments actively adapted to market changes, adjusted production schedules, continued to promote refined management, strengthened production cost control, and improved efficiency. The vast number of employees have worked together to build Strong Technology into a first-class expert in metal intelligent manufacturing.

2024-12-24

A team of five members led by Liu Xishun, Vice General Manager of Strong Technology, and Lu Zejian, General Manager of Intelligent Equipment Division, departed for the International Heat Treatment Exhibition in Russia. At the exhibition site, the crowd surged and the atmosphere was lively. Relevant enterprises and experts in the heat treatment industry from all over the world conducted friendly exchanges to reveal the latest trends and development trends in heat treatment to colleagues.

2024-12-18