Product Series

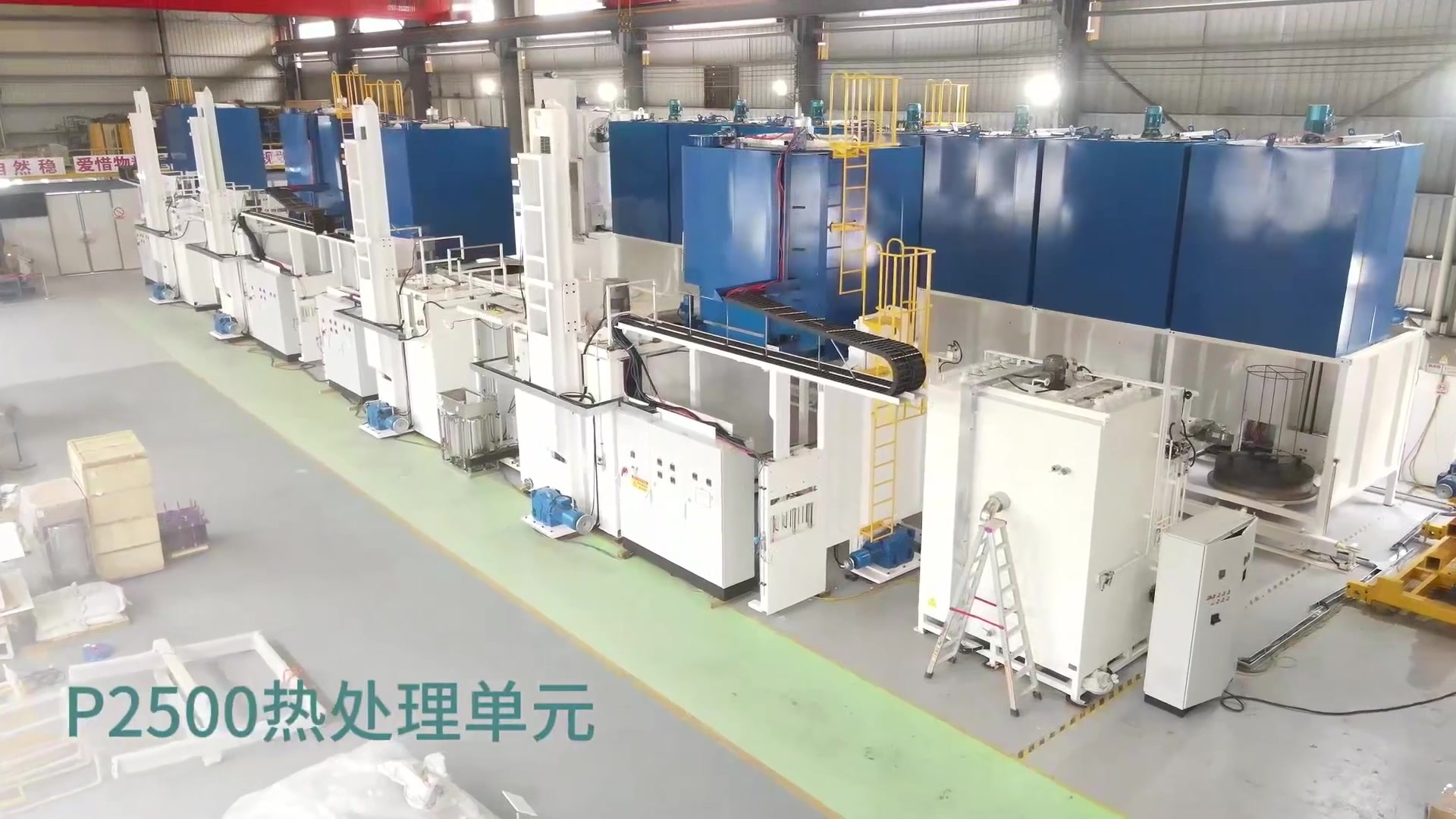

Focus on metal material modification, development and application and shape control processing services, intelligent heat treatment equipment, robots and intelligent equipment manufacturing.

About Strong

Focus on metal material modification, development and application and shape control processing services, intelligent heat treatment equipment, robots and intelligent equipment manufacturing.

Over 20 years of industry experience

Mainly engaged in heat treatment and surface engineering technology and equipment research and development production, at the same time for the Pearl River Delta many manufacturing industry to provide metal heat treatment to strengthen processing services. The equipment produced has been used in aerospace, weapons, ships, automobiles, engineering machinery, petrochemicals, electronic devices, metal products and other industries

More than 90 Honor

7 major provincial and ministerial projects, 29 patent authorizations, 7 invention patents under application, 4 computer software copyrights, presided over and participated in the formulation of 14 national standards, 5 industry standards, and published more than 30 scientific and technological papers

domestic university cooperation

It has been in-depth cooperation with Shanghai Jiaotong University, South China University of Technology and Guangdong University of Technology for more than ten years, and has established a relatively complete school-enterprise cooperative scientific research model that combines production, education and research, and has obtained fruitful research results

International cooperation

In the past ten years, it has successively carried out technical cooperation with Moscow University of Technology in Russia, SOLO Industrial Furnace Company in Switzerland, Schneider TUI Tool Company in Italy and THT Technical Service Association in Japan.

News

Focus on STRONG TECHNOLOGY to learn more about industry information

11-28

Cooperative customers

Provide quality service to customers