PRODUCTS

Muffle Jar

Founded in 2000, focusing on metal material modification, metal material development and application and shape control processing services, intelligent heat treatment equipment, robots and intelligent equipment manufacturing.

Composite corrugated muffle tank

Composite corrugated muffle tank, commonly known as furnace liner, high-end heat treatment furnace core components. The high quality adopts German VDM nickel alloy steel plate, and the high cost performance adopts Swedish Otokumpu materials. Shichuang Technology is Sweden's Outokumpu authorized Chinese stainless steel sales, service and technical support base, which guarantees the original products. It is a wise choice for precision steel belt furnaces, multi-purpose furnaces and high-end mesh belt furnaces.

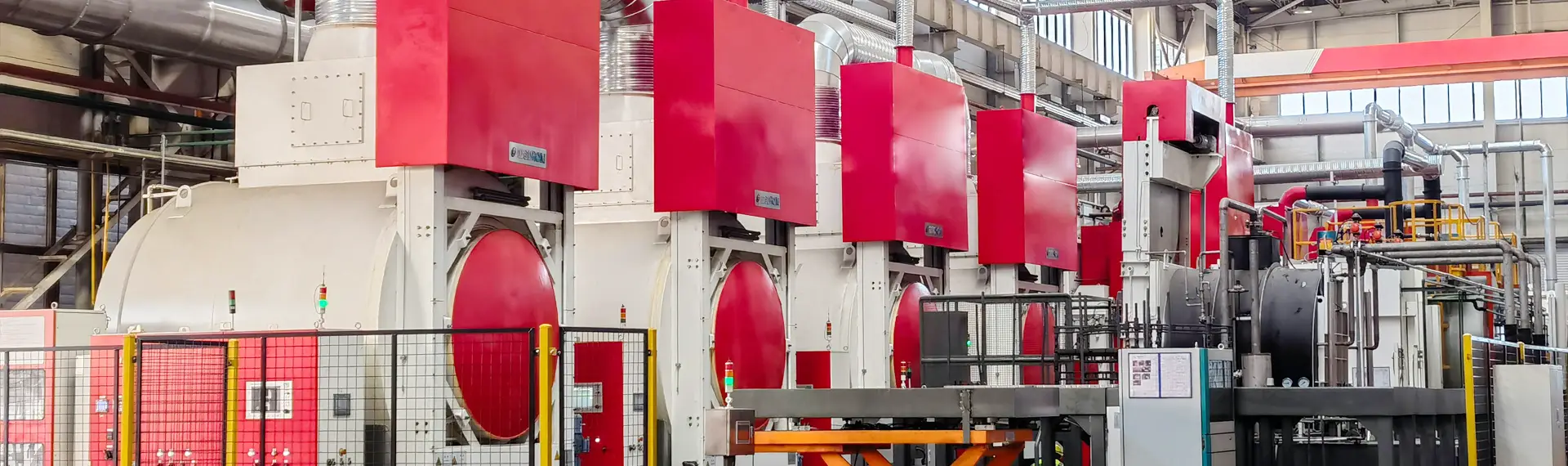

View DetailsStainless Steel Strip Bright Annealing Furnace

From the research and development of stainless steel strip bright annealing furnace, many years of manufacturing and use experience, continuous research and development, from oval muffle tank, through technical refinement, changed to composite corrugated muffle tank compression resistance, anti-expansion, high temperature resistance, longer service life, saving materials, saving costs, are the source of our continuous progress!

View DetailsThe vertical precision strip bright annealing production line produced by Shichuang Technology is used for annealing after rolling of ultra-thin steel strip. The furnace liner is the core component of the annealing furnace and is made of high temperature resistant stainless steel.

View DetailsMesh belt furnace liner: the composite corrugated structure independently designed by shichuang technology is made of Swedish imported plates and high temperature resistant SUS310S plates. after manufacturing, advanced flaw detection technology and air pressure leak test are used to ensure the quality standard.

View DetailsHood-type vertical furnace chamber

Our company can design and manufacture muffle tank size, high temperature, medium temperature and low temperature for users according to user requirements.

View DetailsVertical furnace liner material: 601 high temperature nickel alloy, main supplier: VDM, Germany, use advantages: corrosion resistance, compression resistance, no deformation under high temperature conditions

View DetailsNitriding furnace liner is a relatively sealed space, so that the atmosphere inside the furnace and the atmosphere outside the furnace are separated to ensure that the parts will not be oxidized at high temperatures. The steel strip furnace with corrugated structure is mainly used for bright annealing of stainless steel strip and annealing of other metal strips to ensure high temperature strength and internal oxidation at high temperature.

View DetailsShichuang Technology's patented technology-composite corrugated muffle tank structure. The composite corrugated muffle tank structure is a furnace liner product developed in cooperation with the Swedish Outokumpu. It adopts imported high temperature resistant nickel-based materials and is specially designed to cope with extreme high temperature challenges.

View Details