PRODUCTS

Strong SOLO

Founded in 2000, focusing on metal material modification, metal material development and application and shape control processing services, intelligent heat treatment equipment, robots and intelligent equipment manufacturing.

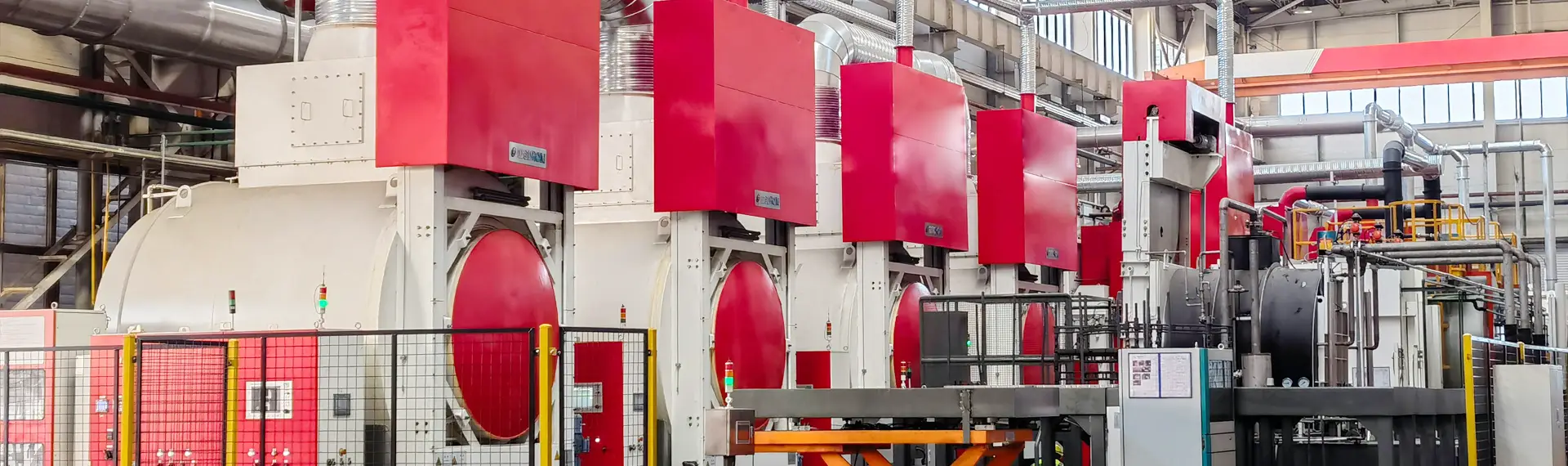

Intelligent flexible heat treatment processing center

Advantages: many kinds of parts, small batch, need to use flexible heat treatment process for heat treatment. The flexible heat treatment production line designed and equipped according to the performance requirements of heat treatment components can flexibly select quenching (oil quenching, water quenching), tempering, normalizing, annealing, carburizing and other heat treatment processes, and use a computer integrated control management system to realize automatic loading and unloading of robots, automatic execution of heat treatment process parameters and online monitoring, real-time control and remote monitoring, and intelligent arrangement of furnace batch production. The verification test results show that the flexible heat treatment production line meets the design requirements.

View DetailsHeat Treatment Application of Mechanical Equipment Parts

Guangdong Shichuang's bottom-loading vertical multi-purpose furnace has been developed for many years, with mature technology and stable production. Swiss imported automatic control system and international brands of high-quality key parts. The bottom-loading vertical multi-purpose furnace adopts the structure of separate design of furnace and quenching tank, and can be equipped with a variety of quenching media (oil, nitrate salt, water, etc.) according to the production needs, which is conducive to future expansion. At the same time, the atmosphere of the bottom charging furnace is fast, precise, controllable and uniform, which is suitable for the flexible production of precision parts with high requirements of many varieties. Now the maximum loading capacity of up to 1500kg.

View DetailsApplication of Heat Treatment for Fine Parts

The bottom loading vertical multi-purpose furnace adopts the split structure of furnace and groove, and the vertical axial design. The quenching transfer time is short, the temperature and atmosphere are converted quickly, and the heat treatment can be realized with less distortion without oxidation and decarburization. Through the computer simulation design of the furnace atmosphere fluid mechanics, the structure of the furnace circulation system is continuously improved, the air short circuit is reduced, the temperature and atmosphere uniformity in the furnace are improved, the product qualification rate is greatly improved, and the product quality is consistent.

View DetailsHeat Treatment Application of Auto Parts

For the heat treatment of key components such as automobiles, the bottom-loading vertical multi-purpose furnace has obvious advantages in thin-layer carburizing, precision carburizing, less distortion heat treatment, and improving the comprehensive performance of strength and toughness. It can meet the performance requirements of precision heat treatment and meet the technical requirements of AMS2750D and GB/T308252014.

View DetailsHardware clean energy-saving heat treatment application

The bottom-loading vertical multi-purpose furnace has a complete environmental protection device, which can completely replace the salt bath furnace and the lead bath furnace, and meets the requirements of modern clean and energy-saving heat treatment. And its high degree of automation, can achieve a variety of processes. A bottom-loading vertical multi-purpose furnace production line can replace all the traditional heat treatment equipment in the original workshop, improve production efficiency and quality, and improve the working environment.

View DetailsVertical nitriding furnace with bottom charge

Advantages: The precision controlled atmosphere nitriding furnace inherits the advantages of the bottom-loading vertical multi-purpose furnace, with strong process adaptability, flexible operation and precise control of the nitriding process. Material: brand: Shichuang technology

View DetailsPrecision controlled atmosphere vacuum pulse well type nitriding furnace

Advantages: The well-type furnace is suitable for workpieces such as long shafts. From simple independent heat treatment furnaces to the most complex fully automated systems, accurate data analysis plays a solid role in the traceability and stability of enterprise products. Each device is specially customized for you!

View DetailsIntelligent deep well heat treatment production line

The intelligent deep well-type controlled atmosphere heat treatment production line is specially designed for the carburizing, quenching and tempering of long-axis workpieces, and is applied to automobile shafts, high-speed rail shafts, subway shafts, special excavating machines and other industries. With its unique heat treatment method, the long workpiece deformation and other advantages, won the China Mechanical Engineering Society awarded the Science and Technology Innovation Award.

View Details